Intro: The Common “Interface Magicians”

Surfactants are the undetectable heroes of contemporary industry and every day life, located all over from cleansing products to drugs, from oil extraction to food handling. These unique chemicals serve as bridges in between oil and water by altering the surface tension of liquids, becoming crucial functional active ingredients in plenty of sectors. This article will certainly give an extensive exploration of surfactants from an international viewpoint, covering their meaning, main types, considerable applications, and the special features of each category, offering a comprehensive referral for industry specialists and interested learners.

Scientific Definition and Working Concepts of Surfactants

Surfactant, short for “Surface area Active Representative,” refers to a course of compounds that can substantially lower the surface area tension of a liquid or the interfacial tension in between 2 phases. These molecules have an one-of-a-kind amphiphilic framework, consisting of a hydrophilic (water-loving) head and a hydrophobic (water-repelling, normally lipophilic) tail. When surfactants are added to water, the hydrophobic tails attempt to run away the liquid setting, while the hydrophilic heads stay in contact with water, triggering the molecules to straighten directionally at the user interface.

This alignment generates numerous vital impacts: reduction of surface stress, promo of emulsification, solubilization, wetting, and foaming. Over the critical micelle concentration (CMC), surfactants create micelles where their hydrophobic tails gather inward and hydrophilic heads deal with external towards the water, thus enveloping oily compounds inside and allowing cleansing and emulsification functions. The global surfactant market reached around USD 43 billion in 2023 and is projected to grow to USD 58 billion by 2030, with a compound yearly growth rate (CAGR) of regarding 4.3%, mirroring their foundational duty in the worldwide economic climate.

(Surfactants)

Key Kind Of Surfactants and International Category Requirements

The worldwide classification of surfactants is normally based on the ionization attributes of their hydrophilic teams, a system widely acknowledged by the worldwide academic and industrial areas. The adhering to 4 classifications represent the industry-standard classification:

Anionic Surfactants

Anionic surfactants carry an adverse charge on their hydrophilic team after ionization in water. They are the most created and commonly applied type around the world, accounting for concerning 50-60% of the overall market share. Typical examples include:

Sulfonates: Such as Linear Alkylbenzene Sulfonates (LAS), the main component in laundry cleaning agents

Sulfates: Such as Salt Dodecyl Sulfate (SDS), widely used in individual care items

Carboxylates: Such as fat salts discovered in soaps

Cationic Surfactants

Cationic surfactants carry a positive fee on their hydrophilic team after ionization in water. This category uses great antibacterial homes and fabric-softening capabilities yet generally has weaker cleaning power. Key applications include:

Quaternary Ammonium Substances: Made use of as disinfectants and fabric conditioners

Imidazoline Derivatives: Utilized in hair conditioners and individual treatment products

Zwitterionic (Amphoteric) Surfactants

Zwitterionic surfactants bring both positive and unfavorable costs, and their buildings differ with pH. They are normally light and very compatible, extensively made use of in high-end individual care products. Regular reps include:

Betaines: Such as Cocamidopropyl Betaine, utilized in light shampoos and body cleans

Amino Acid Derivatives: Such as Alkyl Glutamates, utilized in high-end skin care products

Nonionic Surfactants

Nonionic surfactants do not ionize in water; their hydrophilicity originates from polar teams such as ethylene oxide chains or hydroxyl groups. They are insensitive to difficult water, usually generate much less foam, and are commonly used in different commercial and durable goods. Key kinds include:

Polyoxyethylene Ethers: Such as Fatty Alcohol Ethoxylates, utilized for cleansing and emulsification

Alkylphenol Ethoxylates: Commonly made use of in commercial applications, however their use is restricted because of environmental problems

Sugar-based Surfactants: Such as Alkyl Polyglucosides, stemmed from renewable resources with great biodegradability

( Surfactants)

Global Perspective on Surfactant Application Fields

House and Personal Care Industry

This is the biggest application location for surfactants, representing over 50% of global intake. The item array extends from laundry cleaning agents and dishwashing fluids to shampoos, body cleans, and tooth paste. Demand for light, naturally-derived surfactants continues to expand in Europe and The United States And Canada, while the Asia-Pacific region, driven by population growth and raising non reusable revenue, is the fastest-growing market.

Industrial and Institutional Cleansing

Surfactants play an essential function in industrial cleansing, consisting of cleansing of food processing equipment, car cleaning, and steel treatment. EU’s REACH guidelines and US EPA standards impose rigorous rules on surfactant selection in these applications, driving the growth of more environmentally friendly alternatives.

Petroleum Removal and Enhanced Oil Recovery (EOR)

In the oil sector, surfactants are used for Boosted Oil Recuperation (EOR) by reducing the interfacial tension between oil and water, aiding to launch recurring oil from rock developments. This technology is commonly made use of in oil fields in the center East, The United States And Canada, and Latin America, making it a high-value application location for surfactants.

Agriculture and Pesticide Formulations

Surfactants function as adjuvants in pesticide formulas, boosting the spread, bond, and infiltration of active components on plant surfaces. With expanding global concentrate on food protection and sustainable farming, this application location remains to expand, especially in Asia and Africa.

Pharmaceuticals and Biotechnology

In the pharmaceutical sector, surfactants are made use of in medication shipment systems to improve the bioavailability of improperly soluble medicines. Throughout the COVID-19 pandemic, particular surfactants were made use of in some vaccine formulas to stabilize lipid nanoparticles.

Food Sector

Food-grade surfactants function as emulsifiers, stabilizers, and foaming agents, frequently located in baked goods, ice cream, chocolate, and margarine. The Codex Alimentarius Compensation (CODEX) and national governing companies have strict standards for these applications.

Textile and Leather Processing

Surfactants are made use of in the textile sector for wetting, cleaning, coloring, and completing procedures, with considerable need from global fabric manufacturing centers such as China, India, and Bangladesh.

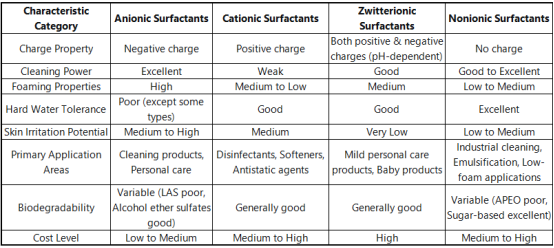

Contrast of Surfactant Types and Choice Guidelines

Choosing the best surfactant needs consideration of several aspects, consisting of application requirements, cost, environmental conditions, and regulative requirements. The complying with table sums up the key qualities of the four main surfactant classifications:

( Comparison of Surfactant Types and Selection Guidelines)

Secret Factors To Consider for Picking Surfactants:

HLB Value (Hydrophilic-Lipophilic Equilibrium): Guides emulsifier selection, varying from 0 (totally lipophilic) to 20 (totally hydrophilic)

Environmental Compatibility: Consists of biodegradability, ecotoxicity, and eco-friendly raw material web content

Regulatory Compliance: Should follow local laws such as EU REACH and United States TSCA

Efficiency Demands: Such as cleaning efficiency, lathering qualities, viscosity inflection

Cost-Effectiveness: Balancing performance with overall formula cost

Supply Chain Stability: Effect of global events (e.g., pandemics, problems) on resources supply

International Trends and Future Overview

Currently, the worldwide surfactant market is greatly influenced by lasting advancement principles, local market demand distinctions, and technical technology, exhibiting a varied and vibrant transformative path. In terms of sustainability and environment-friendly chemistry, the international pattern is extremely clear: the market is increasing its shift from reliance on nonrenewable fuel sources to making use of renewable resources. Bio-based surfactants, such as alkyl polysaccharides derived from coconut oil, hand kernel oil, or sugars, are experiencing proceeded market need growth because of their exceptional biodegradability and low carbon footprint. Especially in mature markets such as Europe and North America, strict environmental guidelines (such as the EU’s REACH regulation and ecolabel certification) and increasing consumer choice for “all-natural” and “environmentally friendly” products are collectively driving formulation upgrades and raw material alternative. This change is not limited to basic material resources yet prolongs throughout the entire item lifecycle, including creating molecular structures that can be swiftly and completely mineralized in the atmosphere, enhancing production processes to reduce power consumption and waste, and designing safer chemicals in accordance with the twelve principles of environment-friendly chemistry.

From the viewpoint of local market characteristics, various regions around the world exhibit distinctive development focuses. As leaders in modern technology and regulations, Europe and North America have the highest requirements for the sustainability, safety, and useful qualification of surfactants, with high-end individual treatment and house products being the main battleground for innovation. The Asia-Pacific region, with its big populace, fast urbanization, and expanding middle course, has come to be the fastest-growing engine in the international surfactant market. Its demand currently focuses on cost-efficient solutions for standard cleaning and personal treatment, but a fad in the direction of high-end and eco-friendly products is significantly obvious. Latin America and the Center East, on the various other hand, are showing solid and specialized need in certain commercial sectors, such as enhanced oil healing innovations in oil removal and farming chemical adjuvants.

Looking in advance, technological technology will certainly be the core driving pressure for market progression. R&D focus is strengthening in a number of vital directions: to start with, establishing multifunctional surfactants, i.e., single-molecule frameworks possessing multiple properties such as cleansing, softening, and antistatic residential properties, to streamline formulas and enhance efficiency; second of all, the surge of stimulus-responsive surfactants, these “clever” molecules that can reply to adjustments in the exterior atmosphere (such as particular pH worths, temperature levels, or light), allowing precise applications in circumstances such as targeted medicine launch, managed emulsification, or petroleum removal. Finally, the commercial capacity of biosurfactants is being more checked out. Rhamnolipids and sophorolipids, produced by microbial fermentation, have wide application potential customers in ecological removal, high-value-added individual treatment, and agriculture due to their outstanding environmental compatibility and one-of-a-kind homes. Finally, the cross-integration of surfactants and nanotechnology is opening up new possibilities for medicine shipment systems, advanced products preparation, and energy storage space.

( Surfactants)

Secret Considerations for Surfactant Option

In functional applications, picking one of the most ideal surfactant for a particular item or process is a complicated systems engineering task that needs detailed factor to consider of several related variables. The key technical indicator is the HLB worth (Hydrophilic-lipophilic balance), a numerical scale made use of to quantify the relative stamina of the hydrophilic and lipophilic components of a surfactant particle, commonly ranging from 0 to 20. The HLB worth is the core basis for picking emulsifiers. For instance, the preparation of oil-in-water (O/W) solutions usually needs surfactants with an HLB worth of 8-18, while water-in-oil (W/O) emulsions require surfactants with an HLB worth of 3-6. Therefore, making clear the end use the system is the initial step in figuring out the needed HLB worth variety.

Beyond HLB worths, ecological and regulative compatibility has come to be an inevitable constraint around the world. This includes the price and efficiency of biodegradation of surfactants and their metabolic intermediates in the natural surroundings, their ecotoxicity evaluations to non-target microorganisms such as water life, and the percentage of eco-friendly resources of their basic materials. At the regulatory degree, formulators need to make sure that picked active ingredients completely comply with the regulative requirements of the target audience, such as meeting EU REACH registration demands, abiding by appropriate United States Environmental Protection Agency (EPA) guidelines, or passing certain negative listing testimonials in certain nations and areas. Ignoring these variables may cause products being unable to get to the marketplace or substantial brand track record dangers.

Naturally, core performance requirements are the fundamental beginning factor for choice. Depending on the application scenario, top priority ought to be provided to evaluating the surfactant’s detergency, lathering or defoaming buildings, capability to readjust system thickness, emulsification or solubilization security, and meekness on skin or mucous membranes. As an example, low-foaming surfactants are required in dish washer detergents, while hair shampoos may require an abundant soap. These efficiency demands have to be balanced with a cost-benefit evaluation, taking into consideration not just the expense of the surfactant monomer itself, but additionally its enhancement quantity in the formula, its ability to replacement for extra expensive active ingredients, and its impact on the overall cost of the end product.

In the context of a globalized supply chain, the stability and protection of resources supply chains have actually come to be a critical consideration. Geopolitical events, severe weather condition, worldwide pandemics, or threats connected with relying on a single provider can all interfere with the supply of critical surfactant basic materials. As a result, when choosing basic materials, it is needed to assess the diversity of resources resources, the dependability of the maker’s geographical place, and to consider establishing safety and security supplies or discovering compatible different technologies to boost the resilience of the whole supply chain and ensure continual production and steady supply of items.

Supplier

Surfactant is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality surfactant and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, surfactanthina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for , please feel free to contact us!

Tags: surfactants, cationic surfactant, Anionic surfactant

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us